Grooving Explained

Why Groove?

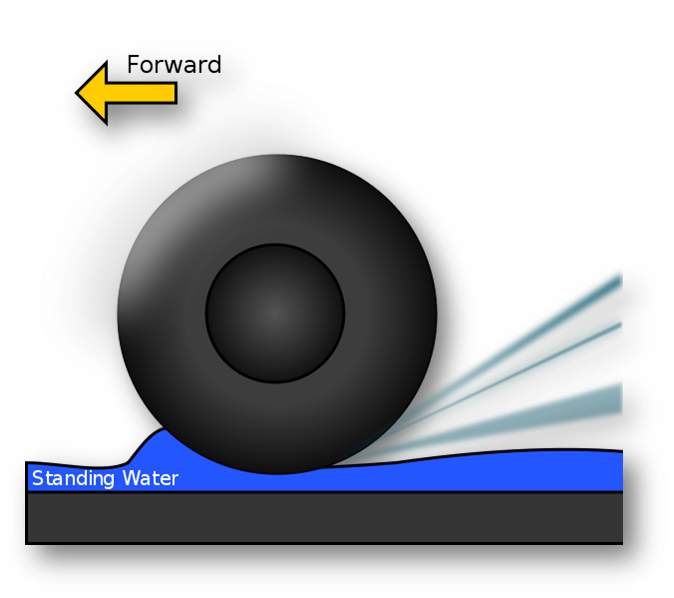

The main function of grooving is to provide an escape route under the aircraft tire for water on the runway to reduce or eliminate Dynamic Hydroplaning. Dynamic Hydroplaning, typically just referred to as hydroplaning, occurs when a tire in motion encounters more water than it can dissipate either through the tire treads or by pushing or shoving the water out of the way.

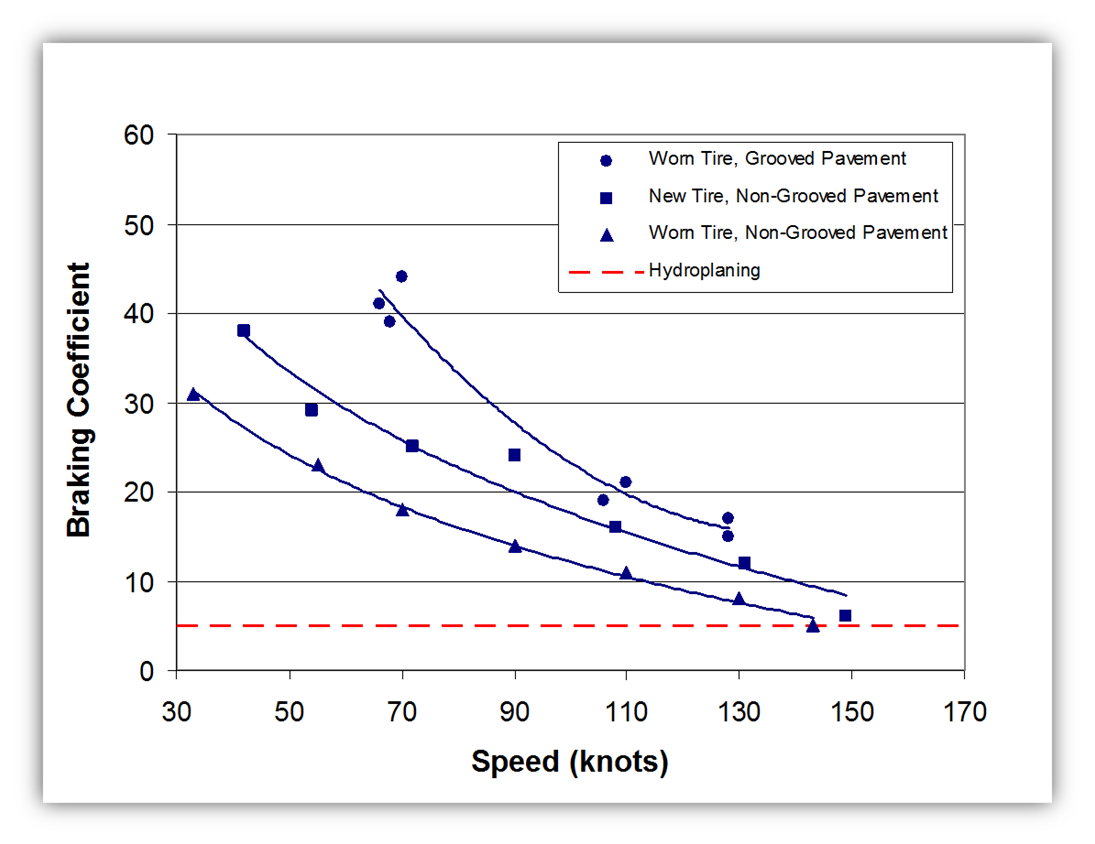

The conditions under which hydroplaning occur are contingent on several factors, primarily speed and the fluid layer thickness as well as tire tread pattern and depth, tire pressure and runway texture. Hydroplaning can result in significantly longer aircraft stopping distance, greater sensitivity to cross winds, potential loss of directional control and a complete dependence on reverse thrust to stop. Grooving is so effective that in the presence of water, totally worn aircraft tires experience better braking on grooved pavement than newly treaded tires on non-grooved pavement.

Mechanics of Grooving

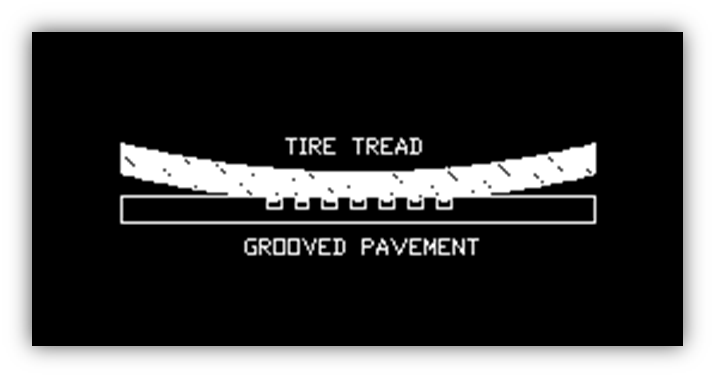

Grooving is always transverse to the direction of travel, and usually to within ten feet (three meters) of the runway edge to allow for the maneuvering of the equipment. The FAA standard is ¼” wide by ¼” deep on 1-1/2” centers (6mm x 6mm x 38mm). Other international standards include 4mm x 4mm x 25mm. Grooving can occur day or night. Additionally, Cardinal, working in conjunction with the FAA, has helped to develop a new method of Trapezoidal Grooving. Please see that section for further information.

Factors Affecting the Cost/Production of Grooving

The type of material to be grooved (concrete or asphalt) is a main factor in determining the price/production. Concrete being harder than asphalt, is typically more expensive. Another major factor is the hardness of the aggregate. A gravel or basalt will usually be harder than a typical limestone and as such will result in lower production and higher costs. The work window for the grooving is another major factor, with longer windows associated with higher productivity and lower costs. Slurry disposal is can more than double the price under certain circumstances and of course local factors such as fuel costs, availability of support equipment, and mobilization.

Other Benefits of Grooving

In addition to greatly reducing or eliminating hydroplaning, grooving also has the benefit of reducing stopping distances on dry pavement through a process called tire tread interlock. Grooving also helps eliminate standing water on the runway and facilitates runway drainage, which also helps to disrupt ice formation.